- Home

- /

- Services

- /

- Simulation Services

Simulation Services

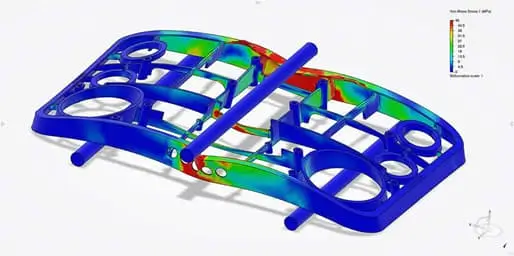

At PLM CAD Utilities, we help businesses enhance product quality and reduce prototype costs through advanced simulation solutions. Our Finite Element Analysis (FEA) and specialized simulation services allow you to test, validate, and optimize your designs under real-world conditions before physical production.

Why Choose Simulation Services?

Simulation offers an intelligent way to evaluate and improve your designs early in the development stage. Instead of relying only on physical prototypes, simulation allows you to explore performance, durability, and safety virtually.

Finite Element Analysis (FEA) at PLM CAD Utilities

FEA is at the core of our simulation services. By applying FEA, we:

- Predict how your design reacts to real-world forces

- Minimize costly prototype iterations

- Improve efficiency with faster design cycles

- Deliver data-driven recommendations for better performance

Key Benefits of Simulation

- Improve product quality while lowering prototype and testing costs

- Evaluate critical design parameters early in the process

- Safely simulate hazardous or impractical load conditions

- Visualize performance through stress, strain, and thermal analysis

- Optimize material usage without compromising strength

- Detect vulnerabilities before fabrication

- Speed up development with fast calculation times

- Reduce R&D and production costs

- Calculate the life cycle and durability of your design

- Maximize cost-efficiency with smart material selection

Our Expertise in Simulation

We specialize in multiple types of simulations, each designed to provide deep insights into your product’s behavior under different conditions.

Static Analysis

Static relates to the time component of the analysis. So it means simply that an analysis that is static takes the assumption that your system doesn’t depend on time.

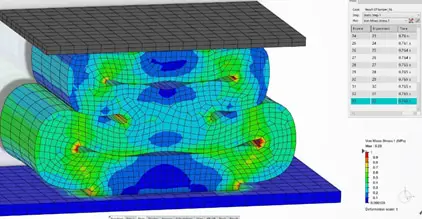

Non-Linear: Perform non-linear analysis using the hyperelastic, viscoelastic materials

We perform highly non-linear analysis when the structure subjected to non-linear effects as follows,

- Material non-linearity (i.e. hyper-elastic, viscoelastic material)

- Geometrical nonlinearity (i.e. large deformation)

- Contact non-linearity (Restriction in DOF)

Dynamic analysis:

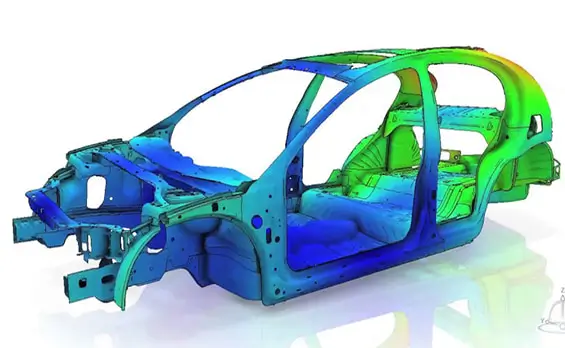

Perform the impact analysis to check the structure behavior

We perform dynamic analysis to check the structure behavior It is useful to consider vehicle impact speeds to describe the different physics involved and that we wish to simulate.

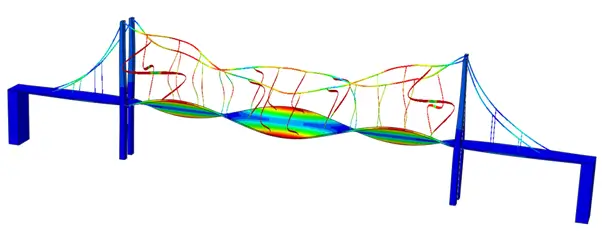

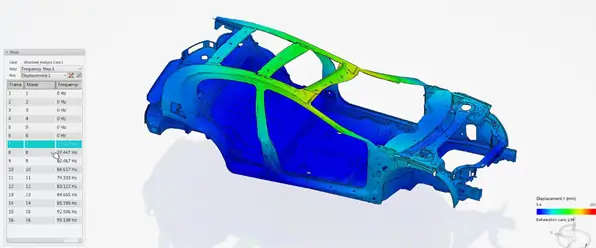

Frequency- Calculating the resonance frequency of the structure to avoid the structure collapse

Modal analysis (Frequency) helps to determine the modes of vibrations and the frequencies at which those modes are triggered. Calculating the resonance frequency of the structure to avoid the structure collapse.

Vibration Analysis

A Random Vibration Analysis (RVA) is used to calculate the system’s structural response to a spectrum of random excitations and non-deterministic loads. Examples of non-deterministic loads include loads generated on a wheel traveling over a rough road or random structural vibrations on the airframe of a helicopter. RVA is conducted in the frequency domain and is usually performed over a large range of frequencies

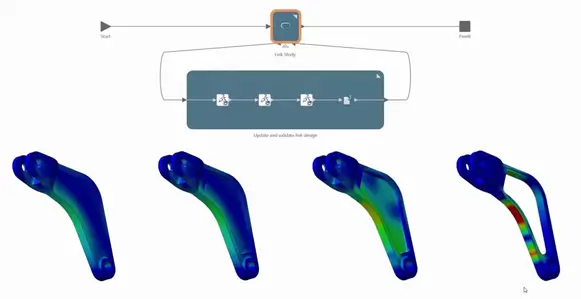

Design Optimization: Reduce the material cost without compromising the product strength.

Design optimization is one of the largest advantages of finite element analysis (FEA). Through gaining a strong understanding of the performance of your product with FEA you can reduce material, prevent stress concentrations, remove bottlenecks, and attain desirable performance attributes.

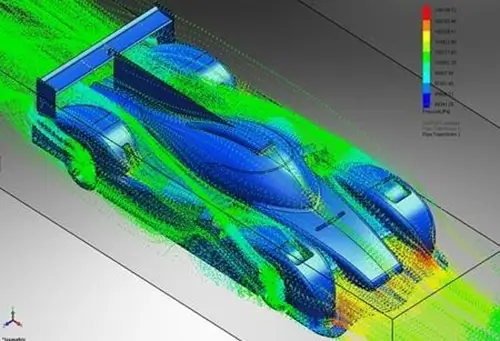

Flow Analysis

- Wind tunnel tests provide the necessary design pressure measurements in the use of the dynamic analysis and control of tall buildings.

- And to calculate lift and drag force on your design

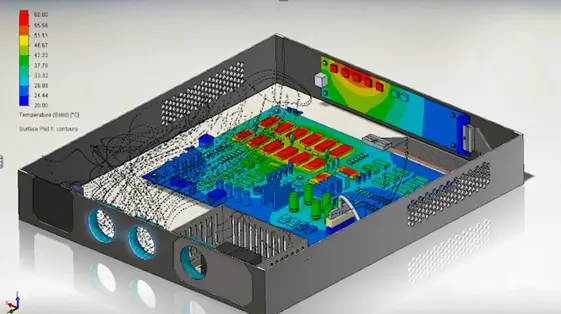

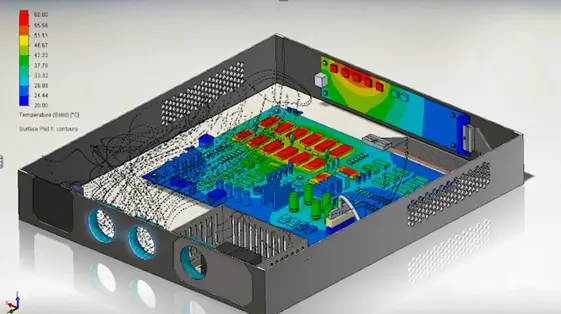

Electronic cooling- Calculate the heat dissipation of heat inside the enclosure to avoid product failure.

We do simulate the heat introduced to a simulation by a battery or other electronics components, along with the cooling effects of fans. This workflow enables you to investigate the battery’s Joule heating behavior.

Thermal Analysis

Heat transfer can also be computed via the finite element method with the added advantage that the thermally induced deformation and stresses can be easily determined and combined with other types of analyses.

Contact Us

Ready to improve product quality and cut prototype costs?

Reach out to PLM CAD Utilities to learn how our simulation expertise can take your designs to the next level. Contact us today to discuss your project.