- Home

- /

- Applications

- /

- Solid Edge

- /

- Solid Edge Business Central Integration-SE2ERP

Seamless Solid Edge and Business Central Integration

Bridge Engineering and Business Workflows Efficiently

Integrating Solid Edge with Dynamics 365 Business Central can eliminate manual data entry, reduce errors, and improve collaboration. With SE2ERP, design teams connect directly to ERP workflows — letting product data flow automatically from CAD to business systems.

What Is SE2ERP?

SE2ERP is a ready-to-install integration tool that syncs Solid Edge product and BOM data with Business Central. It embeds inside Solid Edge as a task pane to preview ERP data, update items, and send BOMs without switching applications.

How It Works

- Install SE2ERP add‑in inside Solid Edge

- Open task pane to view ERP items and BOM preview

- Use mapping templates or scripts to adjust data transfer rules

- Send item/BOM updates from Solid Edge with one click

- Monitor transfers and review logs via reporting dashboard

Watch the Demo

Curious how the integration works in action?

Watch our step-by-step demo and see how Solid Edge connects seamlessly with Dynamics 365 Business Central.

▶️ Watch the SE2ERP Integration Demo on YouTube

Why Choose SE2ERP?

- Eliminate repetitive manual entry that opens room for mistakes

- Make item and BOM data instantly available across teams

- Increase productivity by reducing handoffs and delays

- Maintain version control and audit trails across design and ERP changes

- Accelerate time to production and reduce cost of rework

Key Features of SE2ERP Integration

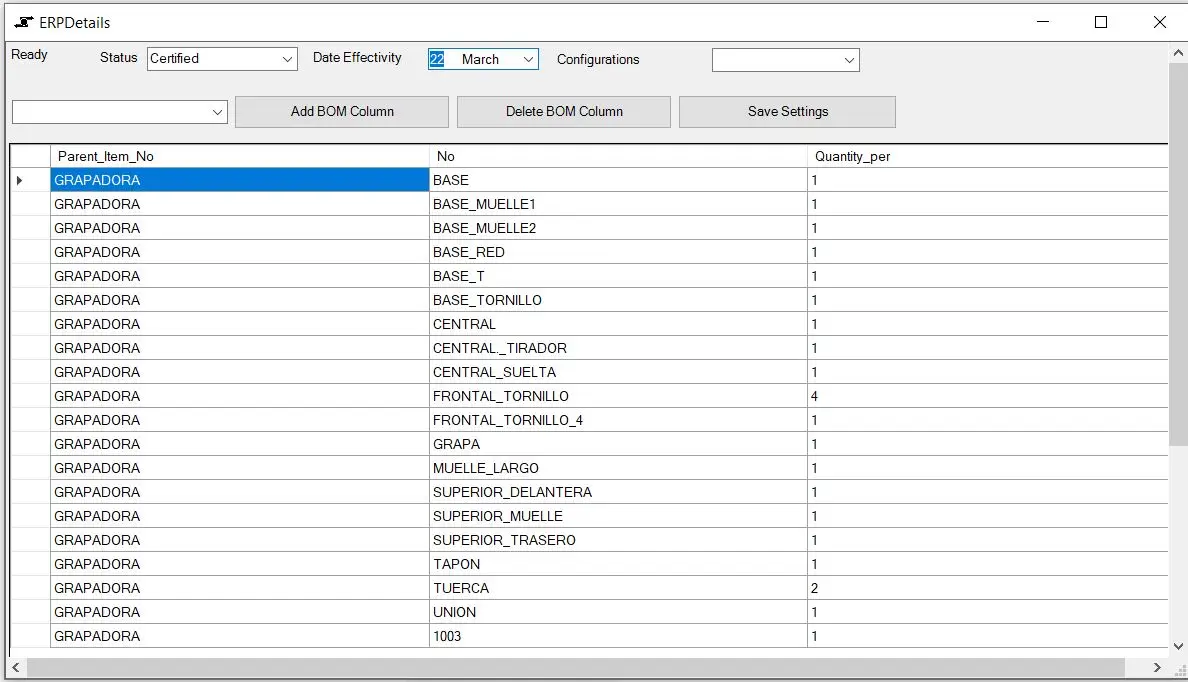

Real-time ERP Data Preview in Solid Edge

- Real-time ERP Data Preview in Solid Edge

- Supports both current and historical BOM versions if versioning is used in ERP.

- View and modify which ERP BOM columns are displayed within Solid Edge; column configurations can be saved for repeated use.

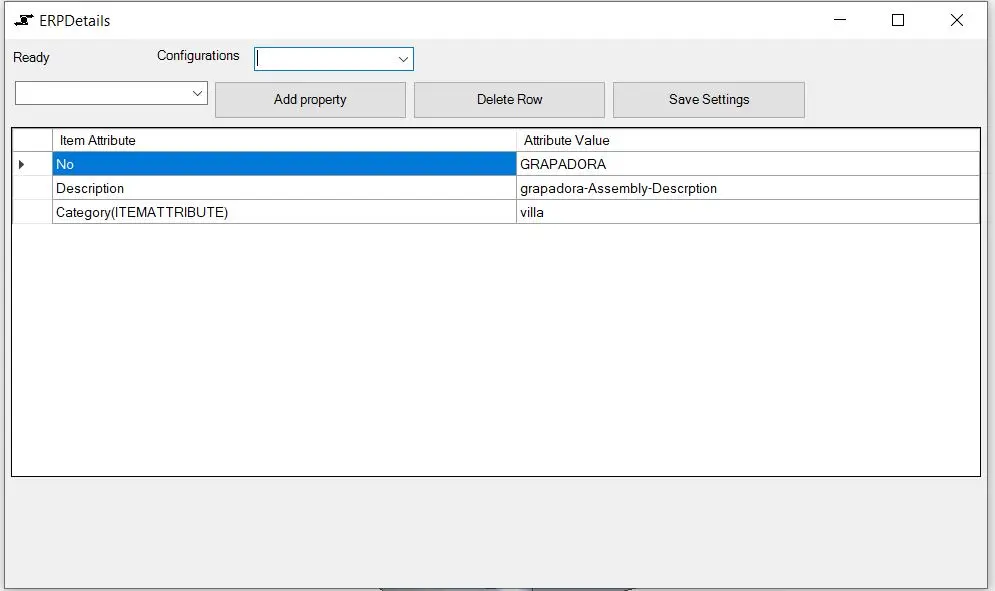

Flexible Configurations and Property Management

- Capability to choose from available BOM configurations and save column/property settings for future use.

- Preview ERP item properties in SOLIDWORKS as well, with customizable property display

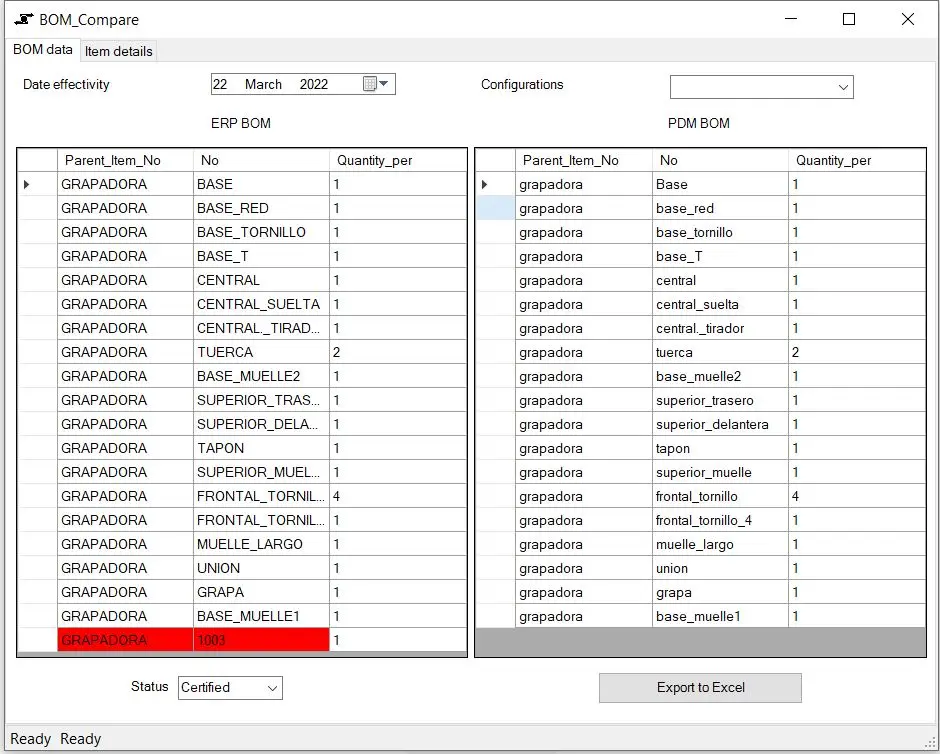

BOM Comparison Functionality

- Directly compare BOMs between Solid Edge and ERP, including comparisons with previous ERP BOM versions if BOM versioning is in place.

- Highlights changes in both BOM structure and item properties at the first child level—a valuable feature for tracking modifications since the last data transfer to ERP.

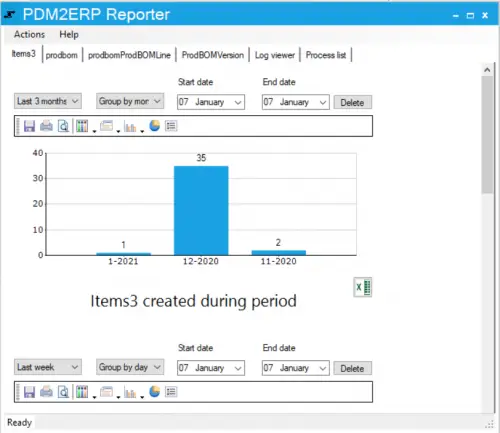

- Utilize the PDM2ERP tool to track all data transfers between Solid Edge and the ERP system.

- View records of items created or updated during any chosen time frame, along with the user responsible for those actions.

Data Tracking and Audit Trail:

Reporting and Analysis

- Export reports (such as BOM or item updates) to Excel for deeper analysis.

- Access historical process logs and error logs within integrated viewers for troubleshooting and performance review.

User Experience Enhancements

- Save personalized preview and comparison configurations, reducing repetitive tasks.

- Review process lists to obtain detailed overviews of completed operations.

Contact Us

Next Step

Interested in streamlining your Solid Edge to ERP workflow?

Contact us to schedule a demo and discuss how SE2ERP can be tailored to your needs.

Ideal For These Industries

SE2ERP supports companies using Solid Edge and Business Central in fast‑moving manufacturing and engineering environments, including:

- Machinery and industrial equipment makers

- Automotive parts and components producers

- Consumer electronics and product engineering firms

- Contract manufacturing and engineering services

Why PLM CAD UTILITIES AS?

With years of experience integrating CAD systems with ERP, we understand both engineering and business sides of product workflows. Our team makes your implementation smooth by delivering solutions that adapt to your operations, minimize disruption, and scale as you grow.